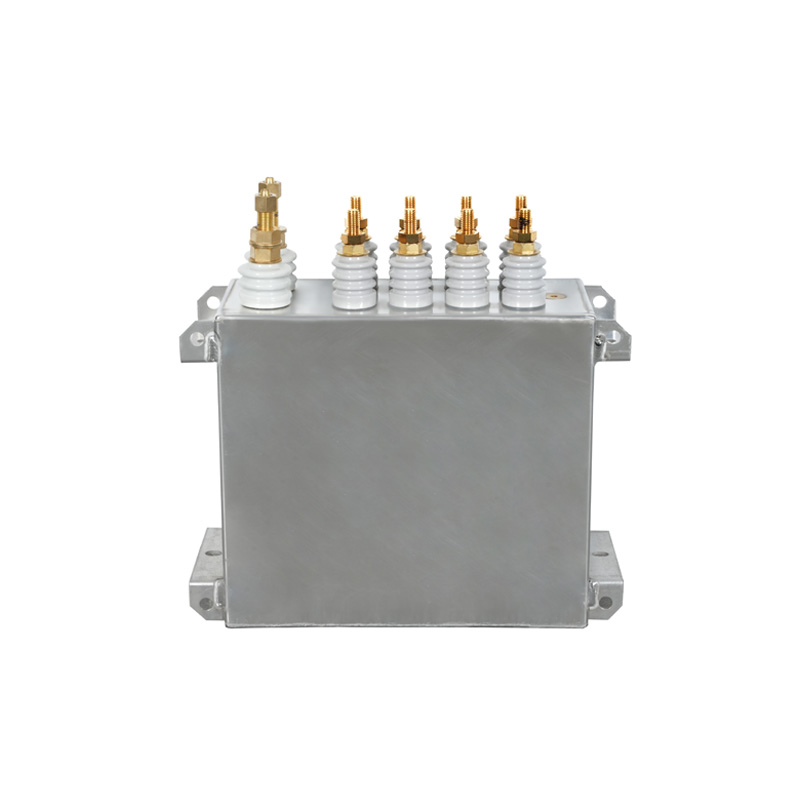

Capacitor de aquecimento de indução refrigerado a água

Capacitor de aquecimento de indução refrigerado a água

Capacitor de aquecimento de indução refrigerado

Capacitor de aquecimento de indução refrigerado

RAM 2200V 3960KVAR 3000Hz Capacitores de aquecimento de indução média de frequência

RAM 2200V 3960KVAR 3000Hz Capacitores de aquecimento de indução média de frequência

No domínio da eletrônica de potência, garantir uma corrente contínua limpa e ...

saber maisCapacitores de tanque de aquecedor por indução desempenham um pa...

saber maisCompreensão Capacitor resfriado a água Fundamentos Os capacitores r...

saber maisCompreendendo os capacitores de alta tensão – princípios básicos e importânci...

saber maisNo complexo mundo da eletrônica moderna, poucas falhas de componentes são tão...

saber maisO motor invisível: por que os capacitores de resfriamento a água são essencia...

saber maisTemos uma equipe de P&D forte e podemos desenvolver e produzir produtos de acordo com os desenhos ou amostras que os clientes ofereceram.

Temos duas de nossas próprias fundições de elenco e uma fábrica de usinagem da CNC. Para que possamos oferecer o preço e os produtos diretamente.

Temos nosso próprio laboratório de testes e equipamentos de inspeção avançada e completa, que podem garantir a qualidade dos produtos.

Nossa produção anual excede 20.000 peças, que podem atender às necessidades dos clientes com diferentes volumes de compra.

Nós nos concentramos no desenvolvimento de produtos de alta qualidade para os mercados de ponta. Nossos produtos estão alinhados com os padrões internacionais e são exportados principalmente para a Europa, América, Japão e outros destinos em todo o mundo.

empresa conta com uma equipe de pós-venda profissional, com profissionais altamente qualificados, vasta experiência técnica e equipamentos de teste avançados. Aderindo à perspectiva científica de desenvolvimento, a empresa mantém um relacionamento próximo com os usuários, mantém intercâmbios técnicos e oferece serviços de produção personalizados e personalizados. A empresa busca produtos personalizados e diferenciados, transformando sua indústria de manufatura de uma voltada para a produção em uma voltada para o serviço. Por meio de um mecanismo de avaliação de uso do produto, a empresa promove projetos de satisfação do usuário e se esforça para atingir zero reclamações dos usuários no pós-venda.

Heat exchange principle: Water-cooled induction heater tank capacitors generate a lot of heat when working. The design of the cooling channel is based on the principle of heat exchange. By allowing cooling water to flow in the channel, the heat generated by the capacitor is absorbed, thereby reducing the temperature of the capacitor. Jiande Antai Power Capacitor Co., Ltd. has 40 years of professional experience. When designing cooling channels, it fully considers the efficiency of heat exchange to ensure that the product can operate stably under various working conditions. The induction heating melting capacitors and other products it produces have effectively solved the heat dissipation problem through reasonable cooling channel design, ensuring the excellent performance of the products, which is one of the reasons why its products have won wide recognition and trust from domestic and foreign customers.

Channel layout: The cooling channel is usually laid out around the heating element of the capacitor to achieve uniform heat dissipation. Common layout methods include spiral and parallel. The spiral channel enables the cooling water to flow in a spiral shape around the capacitor shell, increasing the contact area and contact time between the cooling water and the capacitor, and improving the heat exchange efficiency. The parallel channel is easy to process and install, and can ensure that the cooling water is evenly distributed in a certain area.

Channel size: The size of the cooling channel has an important influence on the cooling effect. If the channel diameter is too large, the cooling water flow rate is large, but the flow rate is low, and the heat exchange efficiency may not be high; if the channel diameter is too small, the flow rate is high, but the water resistance increases, which may lead to an increase in the power of the water pump and easy blockage. Generally speaking, the channel size needs to be determined based on factors such as the heat generation of the capacitor, the flow rate and pressure of the cooling water. During the production process, Jiande Antai Power Capacitor Co., Ltd. will use its own testing laboratory and advanced and complete testing equipment to test cooling channels of different sizes to find the best design solution to ensure product quality.

Optimize the channel inlet design: In order to make the cooling water enter the cooling channel evenly, the design of the inlet is crucial. A diffusion-type inlet can be used to allow the water flow to be evenly dispersed when entering the channel to avoid the situation where the local flow rate is too high or too low. At the same time, a guide plate or diverter is set at the inlet to guide the water flow to each branch channel to ensure the uniform distribution of the water flow.

Adopt reasonable channel shape and structure: The shape and structure of the channel will affect the flow characteristics of the water flow. For example, the use of smooth inner walls can reduce the resistance of the water flow and avoid turbulence or vortexes in the water flow. In addition, setting appropriate spoiler elements in the channel, such as ribs or protrusions, can increase the disturbance of the water flow and improve the heat exchange efficiency, but at the same time, care should be taken to avoid uneven water flow caused by spoiler elements. When designing cooling channels, the R&D team of Jiande Antai Power Capacitor Co., Ltd. will comprehensively consider the shape, structure and arrangement of spoiler elements of the channel to achieve the best cooling effect and water flow uniformity.

Balance channel resistance: In order to ensure that the cooling water flows evenly in each channel, it is necessary to balance the resistance of the channel. For longer or more curved channels, the cross-sectional area of the channel can be appropriately increased to reduce the resistance; for shorter or straight channels, the cross-sectional area can be appropriately reduced to make the resistance of each channel roughly equal. This ensures that the flow distribution of cooling water in different channels is uniform.

Install flow control devices: Installing flow control devices such as flow control valves or flow meters in the cooling system can monitor and adjust the flow of cooling water in real time. By precisely controlling the cooling water flow rate of each channel according to the operating temperature and actual needs of the capacitor, uniform heat dissipation can be achieved.

Regular maintenance and cleaning: Scale, impurities, etc. may accumulate in the cooling channel, affecting the uniformity of the water flow and the heat exchange efficiency. Therefore, the cooling system needs to be maintained and cleaned regularly to keep the channel clean and unobstructed.